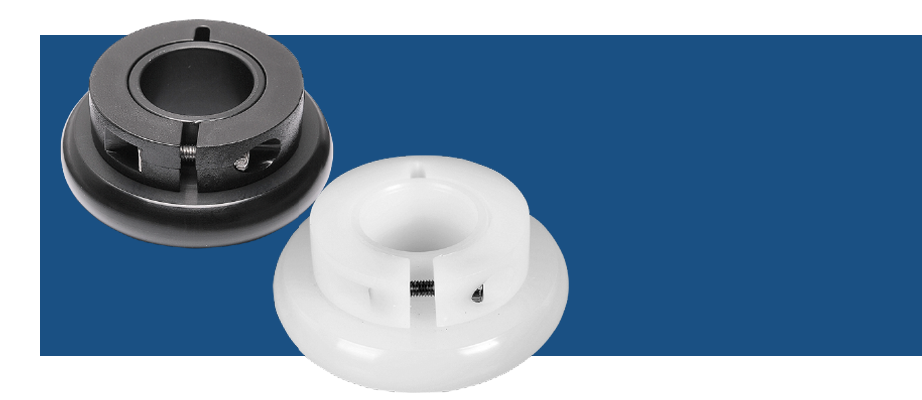

The positioning method is fixed with a stainless steel iron ring and a stop bolt, which is less likely to be deformed due to thermal expansion and contraction.

The positioning ring is made of stainless steel, there is no doubt about material fatigue and deformation, and it is not easy to cause rolling loose or deformation.

技術支援

Roller Material

Roller Quality Control

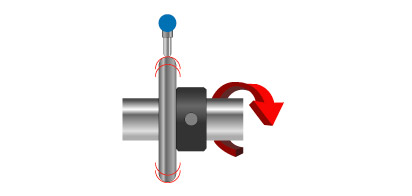

Circularity

Affect:

When the roller vibrates too much up and down, it is easy to jump.

It is easy to cause glass cracks and fragments.

When the roller vibrates too much up and down, it is easy to jump.

It is easy to cause glass cracks and fragments.

The red dotted line in the figure indicates that when the vertical vibration is bad, the roller may produce

Beating phenomenon!

Beating phenomenon!

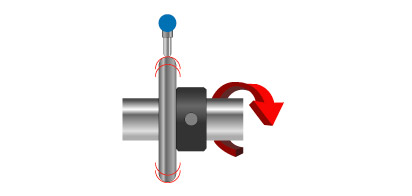

Runout

Affect:

When the left and right deflection of the roller is too large, it is prone to irregular glass bounce

Jump and cause collision and scratches.

When the left and right deflection of the roller is too large, it is prone to irregular glass bounce

Jump and cause collision and scratches.

When the red dashed line in the figure shows poor verticality, the roller may produce

Deflection phenomenon!

Deflection phenomenon!

Surface roughness

Affect:

When the surface of the roller is too rough, it is easy to absorb external dust, and the conveyance marks are obvious (roll marks) and may be more serious.

It will stick to foreign objects and cause scratches.

When the surface of the roller is too rough, it is easy to absorb external dust, and the conveyance marks are obvious (roll marks) and may be more serious.

It will stick to foreign objects and cause scratches.

mirror finish

Roller Surface roughness

Test data

Test data

工程塑膠滾輪編碼說明

Iron ring roller.

POINT

Functional data after assembly

| Runout | Circular Run Out | |

|---|---|---|

Shaft Outer diameter Ø70 below. | Within ± 0.03mm | Within ± 0.03mm |

Shaft Outer diameter Ø70 the above. | Within ± 0.03mm | Within ± 0.03mm |

POM Beam ring Roller

POINT:

The rollers and the shaft are assembled with sliding matching,

and the distance between the rollers can be fine-tuned due to equipment adjustment factors.

Because the roller ring is made of plastic steel, it may become fatigued and hardened due to environmental factors after long-time use.

If the locking bolts are loose or the distance between the rollers is changed, should be paid attention during maintenance.

and the distance between the rollers can be fine-tuned due to equipment adjustment factors.

Because the roller ring is made of plastic steel, it may become fatigued and hardened due to environmental factors after long-time use.

If the locking bolts are loose or the distance between the rollers is changed, should be paid attention during maintenance.

Functional data after assembly

| Runout | Circular Run Out | |

|---|---|---|

Shaft Outer diameter Ø70 below. | Within ± 0.07mm | Within ± 0.05mm |

Shaft Outer diameter Ø70 the above. | Within ± 0.1mm | Within ± 0.07mm |

Quick assembly Roller

POINT

In the design of the roller, the inner ring is tightly positioned after the nut is fixed and locked, and no additional tools are required for assembly.

The distance between the rollers can be adjusted directly according to the use of the equipment, without disassembling the parts for modularization

The distance between the rollers can be adjusted directly according to the use of the equipment, without disassembling the parts for modularization

Functional data after assembly

| Runout | Circular Run Out | |

|---|---|---|

Shaft Outer diameter Ø50 below. | Within ± 0.05mm | Within ± 0.05mm |

Shaft Outer diameter Ø50 below. | Within ± 0.08mm | Within ± 0.08mm |